Khokahano e kentsoeng UL/FM e Amohuoe

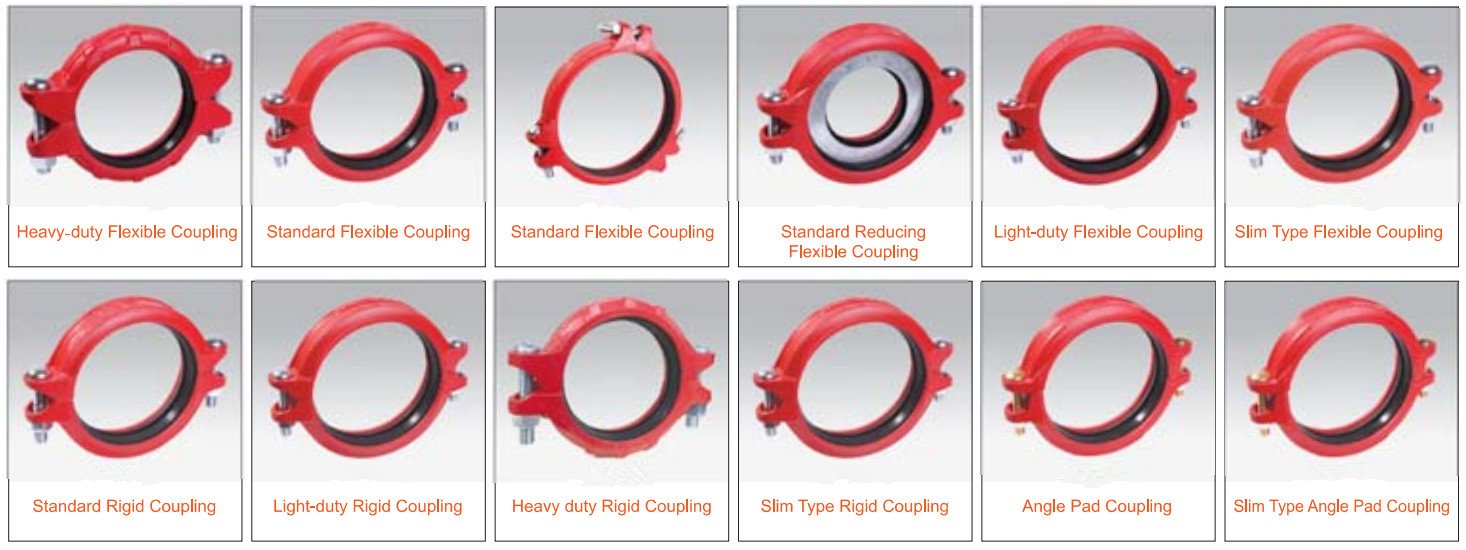

Boima bo boima / bo tloaelehileng / bo bobebe bo feto-fetohang, mokhoa o tloaelehileng oa ho fokotsa ho kopanya ho feto-fetohang, mofuta o monyenyane oa ho kopanya o bonolo;

Mokhoa o tloaelehileng/mosebetsi o bobebe/maqhama a thata-thata, mofuta o mosesane oa ho kopanya o thata;

Angle pad coupling, slim type angle pad coupling;

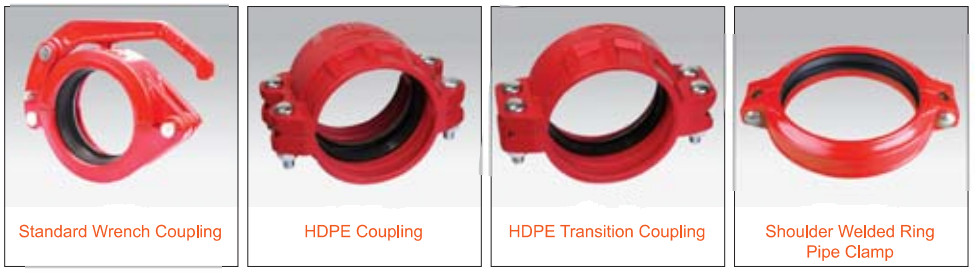

Coupling e tloaelehileng ea wrench, HDPE coupling, HDPE transition coupling, mahetla a tjheselitsoeng ka phala clamp.

1.Ho kenya ka potlako le ka mokhoa o sireletsehileng:

Sistimi ea khokahano ea Grooved e ka phahamisoa ho fihla makhetlo a 10 ka potlako ho feta mekhoa e tloaelehileng ea khokahano joalo ka welding, khokahanyo ea khoele le solder.

Likotsi tsa ho cheselletsa li-welding arcs, khase e hatelitsoeng, mosi o chefo le ho hloka tšireletso ea botho khahlano le mahlo, matsoho, maoto le 'mele.Sistimi ea khokahano ea Grooved e tlosa likotsi tse fapaneng tsa polokeho, joalo ka li-welding arcs le mosi.Ka tsamaiso ea grooved connection, installer e hloka feela ho sebelisa wrench, e leng ea bohlokoa bakeng sa ho kenya tsamaiso ea liphaephe sebakeng se koetsoeng.

Ha li-welding flange li hokahanya, haeba ho se lumellane ha sehlahisoa ho etsahala tšimong, ho ka sebelisoa feela mekhoa e rarahaneng ea ho itšeha e ka sebelisoang ho cheselletsa hape.Leha ho le joalo, sehlahisoa sa sistimi ea khokahano ea groove se ka fetola likarolo tsa sistimi ka likhato tse 360 pele se lokisoa, se boloka nako e kholo ea rework le litšenyehelo tse kholo tse lekanang, ho ntlafatsa ts'ebetso haholo.

2.Ho boloka tikoloho, ha ho na tšilafalo ea lerōle la slag:

Sehlahisoa sa khokahanyo ea groove se na le tikoloho e ntle ho feta ho cheselletsa, ho betla le ho soasoa, hobane ts'ebetso ea ho kenya groove ha e hloke ho futhumatsa, ha ho mocheso o phahameng, ebile ha ho na tšilafalo ea lerōle la welding.

Sehlahisoa se kopantsoeng sa grooved se tšoaroa ka holim'a metsi ka pente ea electrophoretic 'me e na le botsoalle ho feta tikoloho.

Li-couplings tse feto-fetohang li sebelisoa haholo bakeng sa likhokahano tsa liphaephe tse grooved moo lipeipi tse haufi li fellang li lumella palo e itseng ea ho falla ha axial, ho falla ha angular le ho potoloha ha axial.

Li-couplings tse thata ke tsa khokahano ea liphaephe tse grooved.Karolong e kopanetsoeng, lipheletsong tsa pipe e haufi ha lia lumelloa ho ba le ho falla ha axial le ho falla ha angular.