FM/UL E Amohetse 232psi 10 Inch Grooved Flexible Coupling and Fittings

Ho phehella "Boleng bo phahameng bo botle, Phano e Potlakileng, Theko e Hlollang", re thehile tšebelisano ea nako e telele le bareki ba tsoang mose ho maoatle le naheng e 'ngoe le ho fumana maikutlo a phahameng a bareki ba bacha le ba fetileng bakeng sa FM/UL Approved 232psi 10 Inch Grooved Flexible Coupling le Lisebelisoa, Amohela potso ea hau, litšebeletso tse ntle haholo li tla fanoa ka pelo e felletseng.

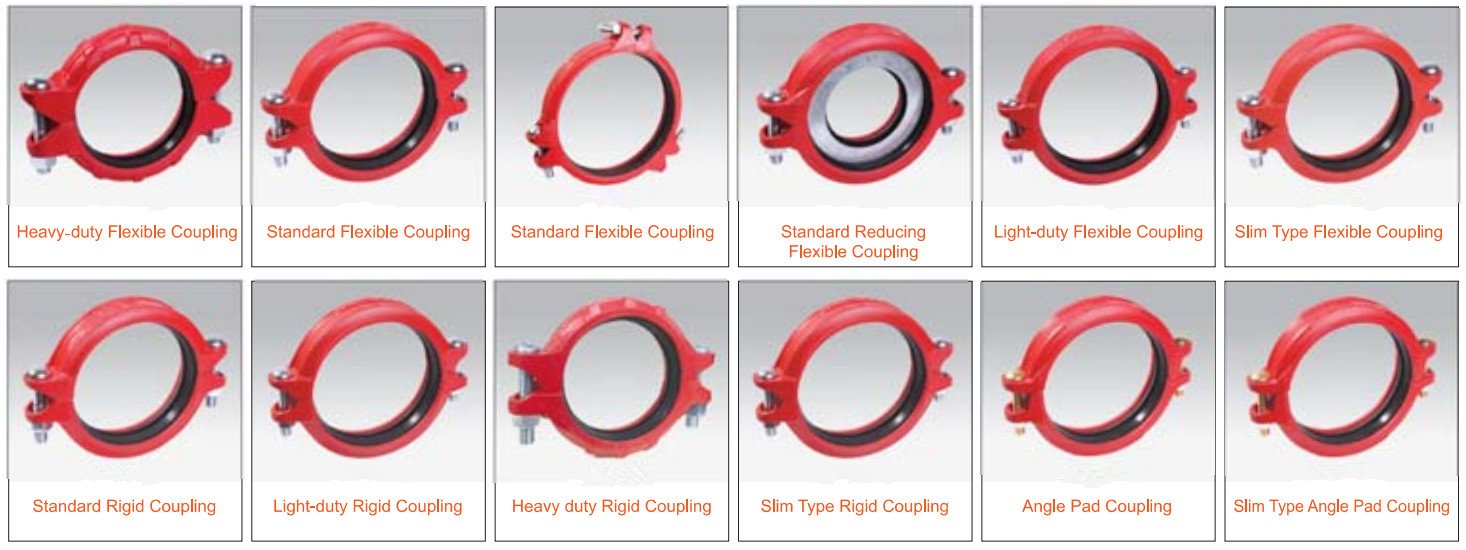

Boima bo boima / bo tloaelehileng / bo bobebe bo feto-fetohang, mokhoa o tloaelehileng oa ho fokotsa ho kopanya ho feto-fetohang, mofuta o monyenyane oa ho kopanya o bonolo;

Mokhoa o tloaelehileng/mosebetsi o bobebe/maqhama a thata-thata, mofuta o mosesane oa ho kopanya o thata;

Angle pad coupling, slim type angle pad coupling;

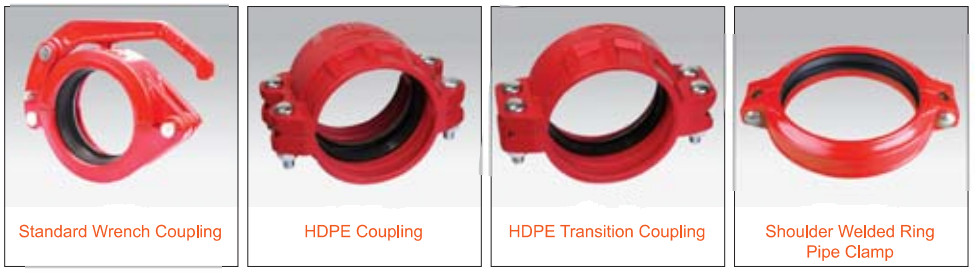

Coupling e tloaelehileng ea wrench, HDPE coupling, HDPE transition coupling, mahetla a tjheselitsoeng ka phala clamp.

1.Ho kenya ka potlako le ka mokhoa o sireletsehileng:

Sistimi ea khokahano ea Grooved e ka phahamisoa ho fihla makhetlo a 10 ka potlako ho feta mekhoa e tloaelehileng ea khokahano joalo ka welding, khokahanyo ea khoele le solder.

Likotsi tsa ho cheselletsa li-welding arcs, khase e hatelitsoeng, mosi o chefo le ho hloka tšireletso ea botho khahlano le mahlo, matsoho, maoto le 'mele.Sistimi ea khokahano ea Grooved e tlosa likotsi tse fapaneng tsa polokeho, joalo ka li-welding arcs le mosi.Ka tsamaiso ea grooved connection, installer e hloka feela ho sebelisa wrench, e leng ea bohlokoa bakeng sa ho kenya tsamaiso ea liphaephe sebakeng se koetsoeng.

Ha li-welding flange li hokahanya, haeba ho se lumellane ha sehlahisoa ho etsahala tšimong, ho ka sebelisoa feela mekhoa e rarahaneng ea ho itšeha e ka sebelisoang ho cheselletsa hape.Leha ho le joalo, sehlahisoa sa sistimi ea khokahano ea groove se ka fetola likarolo tsa sistimi ka likhato tse 360 pele se lokisoa, se boloka nako e kholo ea rework le litšenyehelo tse kholo tse lekanang, ho ntlafatsa ts'ebetso haholo.

2.Ho boloka tikoloho, ha ho na tšilafalo ea lerōle la slag:

Sehlahisoa sa khokahanyo ea groove se na le tikoloho e ntle ho feta ho cheselletsa, ho betla le ho soasoa, hobane ts'ebetso ea ho kenya groove ha e hloke ho futhumatsa, ha ho mocheso o phahameng, ebile ha ho na tšilafalo ea lerōle la welding.

Sehlahisoa se kopantsoeng sa grooved se tšoaroa ka holim'a metsi ka pente ea electrophoretic 'me e na le botsoalle ho feta tikoloho.

Li-couplings tse feto-fetohang li sebelisoa haholo bakeng sa likhokahano tsa liphaephe tse grooved moo lipeipi tse haufi li fellang li lumella palo e itseng ea ho falla ha axial, ho falla ha angular le ho potoloha ha axial.

Li-couplings tse thata ke tsa khokahano ea liphaephe tse grooved.Karolong e kopanetsoeng, lipheletsong tsa pipe e haufi ha lia lumelloa ho ba le ho falla ha axial le ho falla ha angular.

Ho kopanya ho hoholo, re lula re boloka mekoloto ea rona le melemo e tšoanang ho bareki ba rona, re tsitlallela tšebeletso ea rona ea boleng bo holimo ho tsamaisa bareki ba rona.Kamehla amohela metsoalle le bareki ba rona ho tla etela k'hamphani ea rona le ho tataisa khoebo ea rona, haeba u thahasella thepa ea rona, u ka fana ka lintlha tsa hau tsa theko inthaneteng, 'me re tla ikopanya le uena hanghang, re boloka tšebelisano ea rona e tšepahalang haholo. mme o lakatsa eka tsohle tse ka lehlakoreng la hao di lokile.